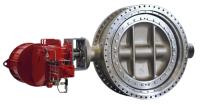

The Metal Seated Triple Offset Butterfly Valve is a variant of the high-performance butterfly valve that features a metal-to-metal seat design, making it suitable for extreme temperatures and high-pressure applications. The triple offset geometry—featuring three precise offsets in the valve design—ensures that the sealing surfaces do not wear under high pressures, while also providing a tight shut-off and minimal leakage. These valves are often used in industries such as oil and gas, petrochemical, and power generation, where the need for a durable and reliable sealing solution is critical. The metal seat allows the valve to handle high temperatures and aggressive media that would otherwise damage traditional elastomeric seated valves.

Specifications and Features:

| Feature | Specification |

|---|---|

| Valve Body Material | Stainless Steel, Carbon Steel, Alloy Steel |

| Pressure Rating | 150 to 2,500 PSI |

| Size Range | 2” to 48” |

| Temperature Range | -50°F to 1,200°F |

| End Connections | Flanged, Butt Weld, Lug |

| Sealing Type | Metal-to-Metal |

| Valve Type | Metal Seated Triple Offset Butterfly Valve |

| Application | Oil & Gas, Power Generation, Chemical Processing |

| Design Standard | API 609, ASME B16.34, ANSI B16.5 |

| Operating Torque | Low torque due to triple offset design |

| Leakage Rate | Very low (Class VI) |