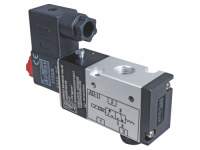

Description: A 3/2 Way Pneumatic Single Solenoid Valve is a type of directional control valve used in pneumatic systems to control the flow of compressed air. The "3/2" designation refers to the valve having three ports and two positions. The three ports include an inlet port, an outlet port, and an exhaust port. The two positions allow the valve to either direct the flow of air from the inlet to the outlet or divert it to the exhaust. The "single solenoid" means that the valve is actuated by a single solenoid coil, which energizes to shift the valve to its second position and de-energizes to return it to its default position.

This type of valve is commonly used in automation, robotics, and industrial applications where controlling the movement of pneumatic actuators or cylinders is needed. It provides precise control over airflow, allowing for reliable operation of machines and processes that require actuators to move in different directions.

Specifications and Features:

| Specification | Details |

|---|---|

| Valve Type | 3/2 Way Pneumatic Single Solenoid Valve |

| Function | Directional Control of Compressed Air |

| Material | Aluminum, Stainless Steel, Brass, Plastic |

| Pressure Rating | Up to 150 psi (varies by material and application) |

| Temperature Rating | -10°C to 80°C (14°F to 176°F) |

| Voltage | 12V DC, 24V DC, 110V AC, 230V AC |

| Connection Type | Threaded, Push-in, or Flanged |

| Port Size | Typically 1/8" to 1" (or custom sizes available) |

| Operation | Single solenoid actuation (electromagnetic) |

| Seal Type | NBR, EPDM, Viton, PTFE |

| Flow Capacity | Variable depending on model and application |

| Applications | Pneumatic Systems, Automation, Robotics, Valve Control |

Features:

Single Solenoid Operation: Simple and cost-effective design using one solenoid coil to control the valve.

Directional Control: Allows precise control of airflow to actuators and cylinders.

Compact and Lightweight: Ideal for applications with space constraints.

Reliable Performance: Quick response and long-lasting operation, suitable for continuous use in industrial environments.

Easy Installation: Available in various connection types for simple installation in pneumatic systems.

Common Applications: Used in automation, robotics, material handling systems, and other pneumatic-based systems where directional control is needed